Discover the Benefits of Polyurea in Canada: Why You Should Invest Now

Polyurea is a rapidly growing, highly versatile material in the coating and lining industry, offering a number of benefits for Canadian businesses. In recent years, polyurea has become increasingly popular for its wide range of applications, durability, and low maintenance requirements. This article will explore the advantages of investing in polyurea in Canada, and why now is the perfect time to do so.

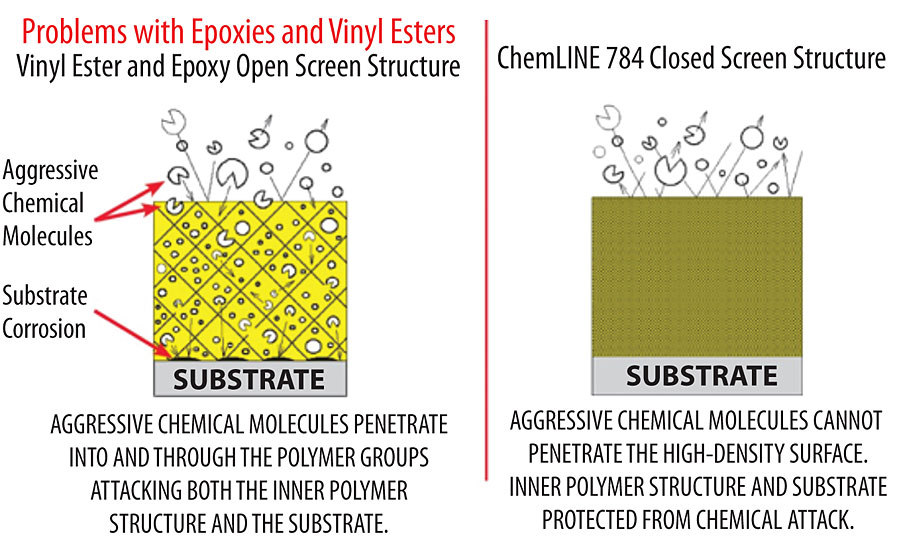

First, polyurea is a cost-effective solution for businesses looking to protect their assets. Polyurea is highly resistant to abrasion, corrosion, and harsh chemicals, making it a great choice for a variety of industrial and commercial uses. This means that businesses can save money on maintenance costs and extend the life of their assets. Additionally, polyurea is incredibly fast-drying, allowing for a quick installation process and minimal disruption to operations.

Second, polyurea is environmentally friendly. Polyurea is a 100 percent solids-based material, meaning that there are no hazardous chemicals or VOCs emitted during its installation. This makes it a great option for businesses looking to reduce their impact on the environment and meet green initiatives. Additionally, polyurea has the added benefit of being a recyclable material, allowing for a sustainable and eco-friendly solution.

Finally, polyurea is incredibly versatile. This material can be used for a variety of applications, from waterproofing to soundproofing, and it can even be used in food-grade applications. This makes it a great choice for a variety of businesses, allowing them to get the most out of their investments.

For all these reasons, now is the perfect time for businesses in Canada to invest in polyurea. This material offers a number of advantages, from cost-effectiveness to environmental friendliness, that make it an ideal choice for a variety of uses. With its versatility, durability, and low maintenance requirements, polyurea is an ideal solution for businesses looking to maximize their investments.

Unlocking the Advantages of Polyurea: What You Need to Know

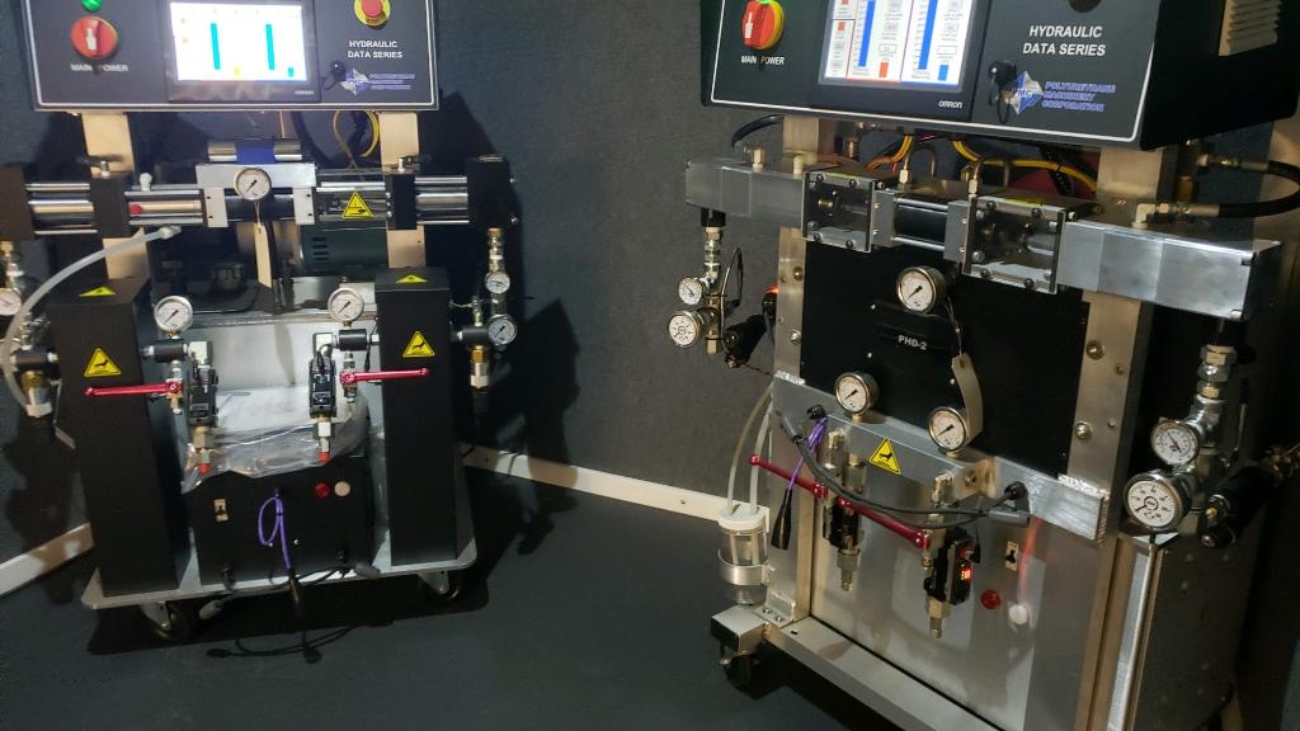

Polyurea is a versatile and durable material used in a variety of applications, ranging from protective coatings to adhesives. It is a high-performance, two-component material that is rapidly gaining popularity in the industrial and commercial sectors. This article will discuss the advantages of polyurea and what you need to know.

One of the most attractive advantages of polyurea is its fast cure time. It can be applied and cured in minutes, resulting in a stronger bond and improved performance over alternative materials. This fast curing time allows for quick product turnaround, reducing downtime and increasing efficiency.

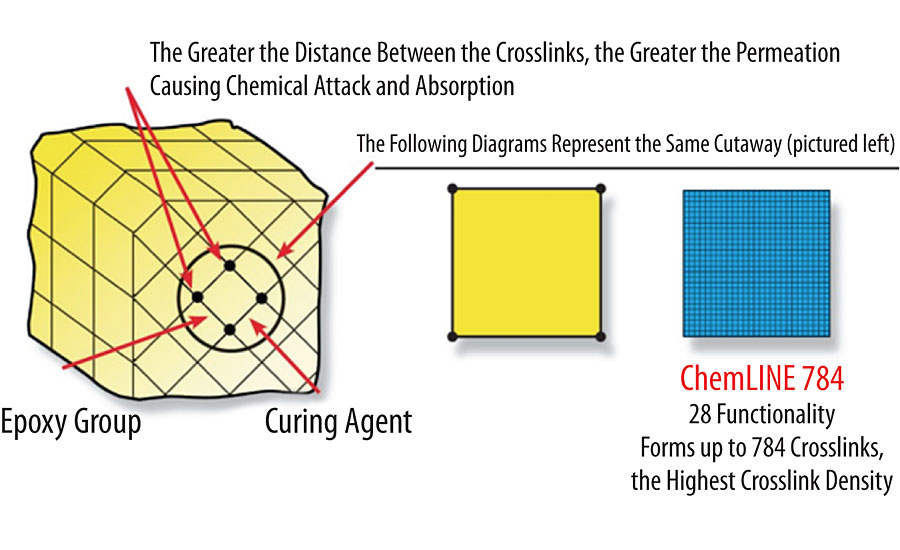

Another benefit of polyurea is its superior strength and durability. It forms a tough and durable coating that can withstand harsh environments and extreme temperatures. Polyurea is also highly resistant to impact, abrasion, and chemical attack, making it a great choice for applications that require long-lasting protection.

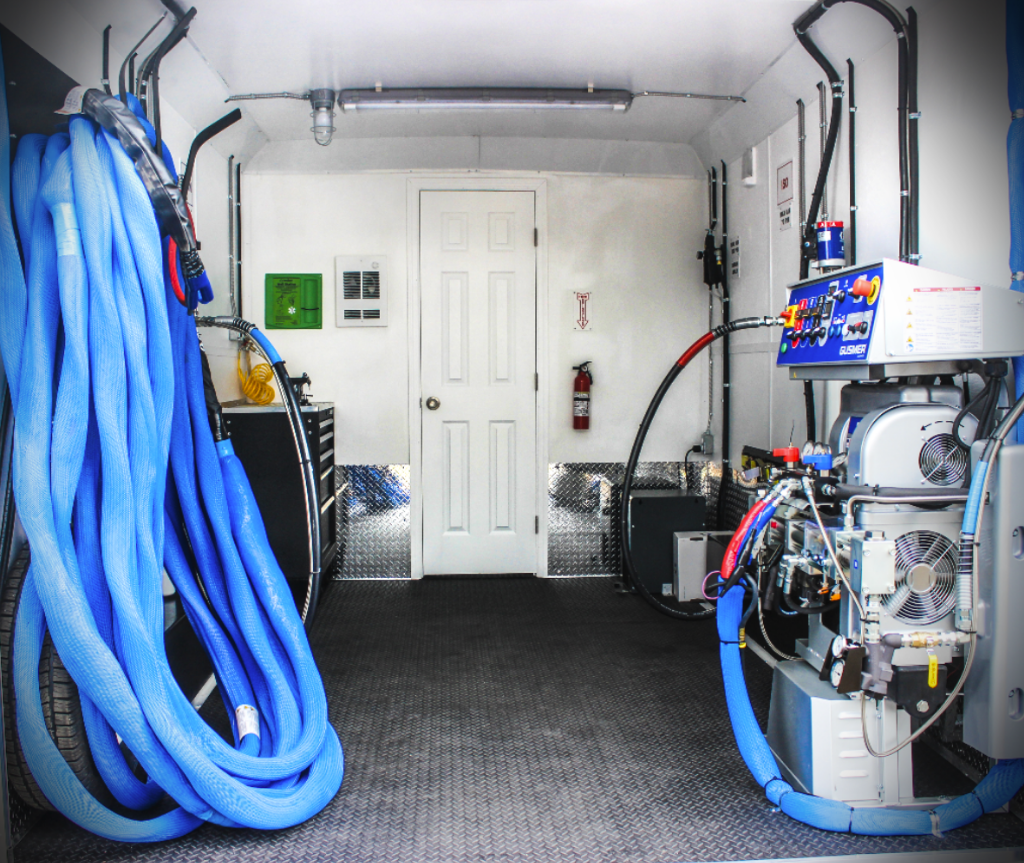

Polyurea is also easy to apply and maintain. It can be sprayed onto almost any surface and can be easily repaired if damaged. Its unique properties also make it easier to clean and maintain, reducing costs and increasing the longevity of the coating.

Finally, polyurea is an environmentally friendly product that is safe for use in indoor and outdoor applications. It is non-toxic and non-flammable, making it a great choice for applications that require a safe and sustainable material.

As you can see, there are many advantages to using polyurea for a variety of applications. However, before you decide to use it, there are a few things you should consider. For instance, polyurea can be difficult to apply in cold temperatures, and it is important to make sure that the surface is properly prepared before applying the material. Additionally, it is important to select the correct grade of polyurea for the application; some grades are more suitable for specific applications than others.

In conclusion, polyurea is a versatile and durable material with many advantages. It is fast curing, strong and durable, easy to apply and maintain, and environmentally friendly. However, it is important to consider the application and environment before selecting the correct grade of polyurea for the job. With the right information, you can unlock the advantages of polyurea and ensure a successful project.

The Lasting Benefits of Polyurea: How to Maximize Your Investment

As businesses and homeowners look for ways to minimize their long-term costs, polyurea is becoming an increasingly popular choice. This versatile material offers a range of benefits, from increased durability to improved protection from the elements. By taking advantage of the many advantages polyurea provides, you can maximize your investment and enjoy the long-term benefits it offers.

Polyurea is often used in industrial, commercial, and residential applications for its superior strength and durability. It is highly resistant to abrasion, corrosion, and impact, making it ideal for applications such as protective coatings, flooring, and roofing. Additionally, its fast-set properties make it ideal for quickly repairing and sealing a variety of surfaces. Polyurea is also highly resistant to chemicals, UV radiation, and extreme temperatures, making it an excellent choice for protecting surfaces from the elements.

Perhaps the greatest benefit of polyurea is its ability to provide long-term protection and prevent the need for costly repairs. Polyurea coatings are highly resistant to wear and tear, meaning they will last longer than traditional coatings. This means that you won’t need to replace them as often, saving you time and money in the long run. Additionally, polyurea coatings can protect surfaces from moisture, which can lead to rot, rust, and mold.

Another benefit of polyurea is its low environmental impact. When applied correctly, it does not release any volatile organic compounds (VOCs) into the atmosphere. This makes it an ideal choice for businesses and homeowners looking to reduce their environmental footprint. Additionally, polyurea coatings can be recycled and reused, making them an economical and sustainable choice.

Finally, polyurea coatings are highly customizable. There are many different formulations available, allowing you to choose a solution that fits your needs. You can also choose from a variety of colors and textures, allowing you to create a unique look for your space.

By taking advantage of the many benefits polyurea provides, you can maximize your investment and enjoy the long-term benefits it offers. From increased durability and protection from the elements to its customization options and low environmental impact, polyurea is a great choice for any project.

The Power of Polyurea: Why it’s the Best Choice for Canadian Consumers

Polyurea is a revolutionary new material that is quickly becoming a popular choice for Canadians. It combines the strength of polyurethane with the flexibility of rubber to create a material that is strong, durable, and resistant to damage and wear. Polyurea is quickly becoming a go-to material for Canadian consumers who are looking for a reliable and long-lasting solution.

Polyurea is a two-part epoxy-based liquid that hardens quickly when applied. It is ideal for use on many different surfaces, including metal, wood, concrete, and asphalt. It is often used in industrial and commercial applications, such as coating tanks, pipes, and other equipment. It is also a popular choice for residential applications, such as coating garage floors, decks, and even driveways.

The main advantage of using polyurea is its strength and durability. It has excellent adhesion properties, making it an excellent choice for use in areas that are exposed to harsh conditions, such as extreme temperatures and moisture. It is also resistant to oils, chemicals, and UV radiation, making it a great choice for outdoor applications.

Polyurea is also highly flexible, making it an ideal choice for applications that require a material that can easily bend and conform to different shapes. This makes it an ideal choice for coating pipes, tanks, and other objects with complex shapes. It is also highly resistant to abrasion, which makes it an ideal choice for coating floors and decks.

The fast curing time of polyurea makes it an attractive choice for many applications. It can be applied in a single coat, which means that projects can be completed much faster than with other materials. This can help to save time and money when completing projects.

Overall, polyurea is an excellent choice for Canadian consumers who are looking for a reliable and long-lasting solution. Its strength, durability, flexibility, and fast curing time make it an ideal choice for many applications. It is also resistant to damage and wear, making it an excellent choice for outdoor applications. With its many advantages, polyurea is quickly becoming a popular choice for many different projects.

Maximizing Your Return on Investment With Polyurea: What You Need to Know

Are you considering investing in polyurea for your business? Polyurea is an advanced coating technology that offers a wide range of benefits for industrial and commercial uses. It is a versatile and durable coating that is increasingly being used for a variety of applications, including coating tanks, pipes, and other structures.

Polyurea offers a number of advantages over traditional coatings, including superior protection against corrosion, extreme temperature fluctuations, and wear and tear. It is also highly resistant to harsh chemicals, making it suitable for many industrial and commercial uses. Given these benefits, it is no surprise that many businesses are now investing in polyurea to protect their assets, improve their efficiency, and maximize their return on investment.

In order to maximize your return on investment, there are a few key considerations you should take into account. First and foremost, you should consider the quality of the product you are investing in. Make sure to select a reliable and reputable brand that offers high-quality materials and services. Additionally, you should make sure to purchase polyurea that is correctly specified for the application you are using it for.

It is also important to ensure that your polyurea is properly applied. Make sure to hire a professional contractor who is experienced in applying polyurea correctly. This professional should have the necessary training and experience to ensure that the job is done right.

Finally, you should also consider the maintenance of the polyurea. While the initial investment in polyurea may be significant, regular maintenance can extend its life and help you maximize your return on investment. Make sure to follow the manufacturer’s instructions for cleaning and maintaining your polyurea, and ensure that it is inspected regularly for any signs of wear or damage.

By taking the time to consider these factors, you can ensure that you are making a sound investment in polyurea and maximize your return on investment. With the right product, application, and maintenance, you can enjoy the many benefits of polyurea for years to come.